INICIO>>Products>>Linear Guideway

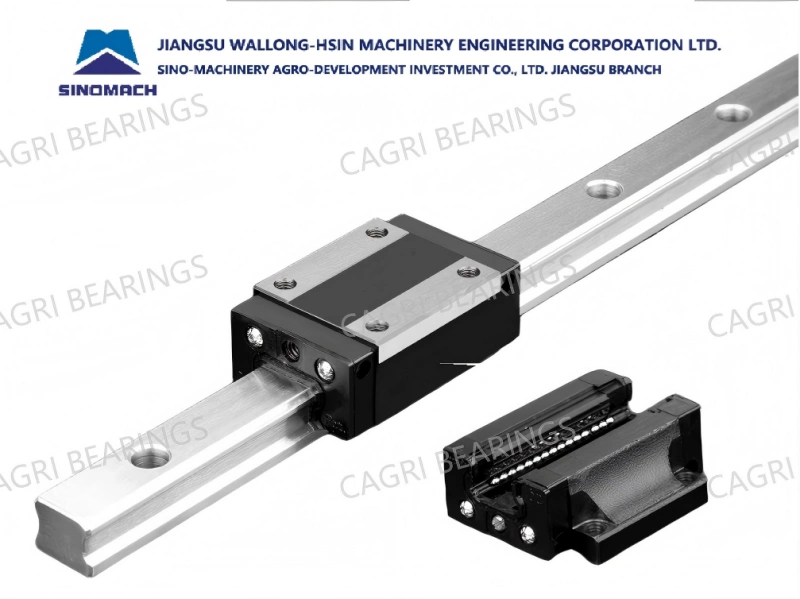

High-Precision Linear Guideway--CAGRI Bearings

Product Overview

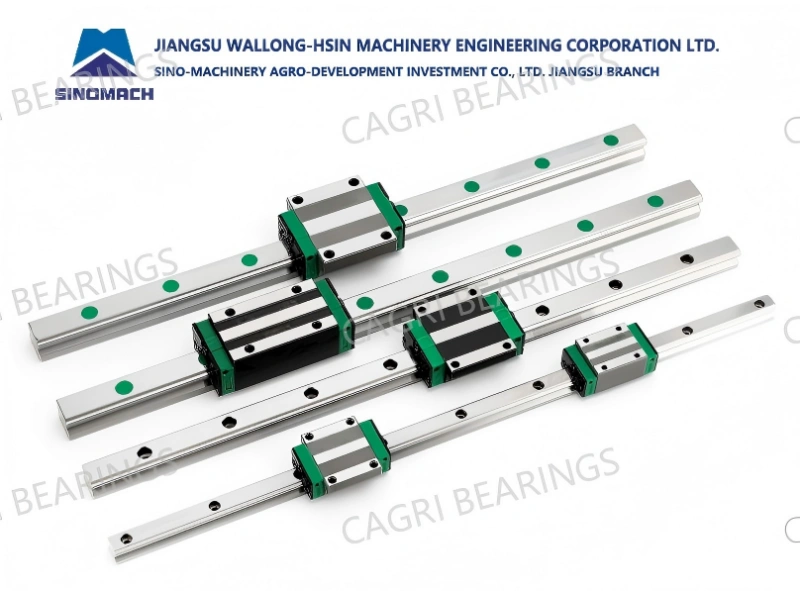

Cagri Bearings- Professional Supplier of Linear Guideways. Linear Guideway (also known as Linear Rail) is a mechanical transmission component that enables high-precision linear reciprocating motion. Its core function is to provide stable guidance for moving parts, reduce frictional resistance, and bear a certain radial and axial load, widely used in automation equipment, machine tools, robots and other fields. The core product categories are divided into Ball Linear Guideways, Roller Linear Guideways, and Needle Linear Guideways according to the rolling element type; according to the structural form, they are divided into Square Type Linear Guideways, Flange Type Linear Guideways, and Miniature Linear Guideways. Among them, Ball Linear Guideways have become the mainstream in the market due to their high precision and low friction characteristics. The models comply with international general standards (such as ISO, JIS, DIN), with common models including HG series (e.g., HG15, HG20, HG30), EG series (EG15, EG20), MGN series (MGN7, MGN9), etc. The specifications cover a guide width of 7mm-100mm and a stroke range of 100mm-5000mm (customized extra-long strokes are supported). The precision grade strictly complies with JIS B 1555 standard, divided into Normal Precision (N class), High Precision (H class), Precision Class (P class), Super Precision (SP class), and Ultra-High Precision (UP class). The mainstream applications are mainly H class and P class, with positioning accuracy up to ±0.01mm/m and repeat positioning accuracy ±0.005mm; the material is high-carbon chromium bearing steel (GCr15) or stainless steel (SUS440C), processed through multiple processes such as quenching, grinding, and superfinishing, with a hardness of HRC60-64 to ensure high strength and wear resistance.

What is Linear Guideway?

Guía lineal is a guiding mechanism that realizes high-precision, low-resistance linear movement of moving parts through rolling contact between rolling elements (balls, rollers, needles) between the guide rail and the slider. It is composed of core components such as guide rail body, slider, rolling elements, cage, seal, and lubrication device. Its core value lies in converting sliding friction into rolling friction, significantly reducing motion resistance (friction coefficient only 0.001-0.003), while ensuring extremely high motion precision and stability, adapting to mechanical systems that require high-frequency reciprocating motion and precise positioning. The application scenarios cover multiple core industries, with a wide range of adapted product types: in the machine tool industry, it is adapted to moving parts such as worktables, turrets, and headstocks of precision machine tools such as machining centers, CNC lathes, milling machines, and grinders; in the automation industry, it is adapted to executive mechanisms of automation equipment such as industrial robots (multi-joint robots, SCARA robots), linear modules, manipulators, and conveyor lines; in the electronic manufacturing industry, it is adapted to motion axes of precision equipment such as PCB drilling machines, chip mounters, semiconductor packaging equipment, and lithium battery pole piece cutting machines; in the automotive manufacturing industry, it is adapted to conveying machinery and positioning mechanisms of automotive welding production lines, painting production lines, and assembly production lines; in addition, it is also widely used in medical equipment (CT machines, MRI equipment), aerospace equipment (component processing machine tools), logistics equipment (stackers, AGV trolleys), printing machinery (digital printers, gravure printers) and other fields, adapting to various linear motion requirements with different loads (10N-50000N) and different speeds (0-5m/s).

CAGRI Linear Guideway Advantages

With cutting-edge manufacturing technology, optimized structural design and strict quality control, CAGRI Linear Guideway has formed six core competitive advantages, leading the industry market:

- Extreme Motion Precision and Stability: Adopt super-precision grinding technology, the guide rail raceway roughness Ra≤0.02μm, the fit clearance between slider and guide rail is controlled within 0.002mm-0.005mm, the positioning accuracy is ±0.008mm/m, and the repeat positioning accuracy is ±0.003mm, far exceeding the industry average; optimize the guide rail cross-sectional structure through finite element analysis, enhance rigidity (radial rigidity increased by 30%, axial rigidity increased by 25%), no vibration or crawling during high-speed operation, ensuring long-term stable operation of the equipment.

- Low Friction and High Operating Efficiency: The rolling elements are high-precision ceramic balls or bearing steel balls, processed through superfinishing and polishing, with excellent surface smoothness; the cage is made of reinforced nylon or phenolic resin material, reducing friction and collision between rolling elements, the friction coefficient is as low as 0.0015, the running resistance is small, and high-speed movement (maximum speed up to 6m/s) can be achieved, while reducing energy consumption and extending the service life of the equipment.

- Super Strong Load-bearing Capacity: Optimize the raceway contact angle (adopt 45° contact angle design) to achieve balanced bearing of radial, axial and overturning moments. The rated dynamic load is 15%-20% higher than that of similar competitors, and the rated static load is 20%-25% higher; the roller-type linear guideway adopts line contact design, with large contact area, which can bear heavy loads and impact loads, adapting to the harsh requirements of heavy machinery and high-precision processing equipment.

- Excellent Sealing and Dust-proof Performance: The two ends of the slider are equipped with a double sealing structure (labyrinth seal + contact seal), which can effectively block the intrusion of dust, iron chips, cutting fluid and other impurities into the raceway, with a protection level of IP67; the guide rail surface is treated with anti-rust coating (galvanizing + passivation or hard chrome plating), and the slider is filled with long-acting grease. It can still maintain good performance under harsh working conditions such as humidity, dust, and cutting fluid splashing, and the maintenance cycle is extended to more than 6000 hours.

- Wide Adaptability and Convenient Installation: The product models are complete, covering micro, small, medium and large full-series specifications, compatible with the installation dimensions of international mainstream brands (such as THK, HIWIN), and can be directly replaced; the guide rail adopts a reference surface design, no complex debugging is required during installation, and it can be quickly fixed through positioning pins or bolts, greatly improving installation efficiency; customize services are supported, and the guide rail length, slider type (flange type, square type), sealing structure, lubrication method, etc. can be adjusted according to customer needs to meet special application scenarios.

Solicitud

Machine Tool Industry | |

Metal Cutting Machine Tools | CNC machining centers, CNC lathes, milling machines, grinders, boring machines, gear cutting machines, EDM machines |

Forming Machine Tools | Punching machines, bending machines, shearing machines, drawing machines, extrusion machines, powder molding machines |

Automation & Robotics Industry | |

Industrial Robots | Multi-joint robots, SCARA robots, Delta robots, collaborative robots, palletizing robots |

Automation Equipment | Linear modules, electric sliding tables, manipulators, conveyor lines, sorters, assembly workstations |

Electronic Manufacturing Industry | |

Semiconductor Equipment | Wafer cutting machines, lithography machines, etching machines, semiconductor packaging equipment, probers |

Electronic Assembly Equipment | PCB drilling machines, chip mounters, reflow ovens, AOI inspection equipment, lithium battery pole piece cutting machines, battery assembly lines |

Automotive Manufacturing Industry | |

Automotive Production Lines | Welding production line conveying equipment, painting production line robotic arms, assembly production line positioning mechanisms, automotive parts processing machine tools |

Automotive Components | Car seat adjustment mechanisms, sunroof slide rails, electric tailgate guide rails, gearbox shift mechanisms, steering system guide components |

Medical Equipment Industry | |

Diagnostic Equipment | CT machines, Magnetic Resonance Imaging (MRI) equipment, ultrasonic diagnostic instruments, biochemical analyzers, blood analyzers |

Therapy & Rehabilitation Equipment | Surgical robots, radiotherapy equipment, infusion pumps, rehabilitation training equipment, prosthetic joint guide mechanisms |

Logistics & Warehousing Industry | |

Logistics Conveying Equipment | AGV trolleys, RGV rail cars, intelligent sorting lines, conveyors, stackers, automated warehouse shelf moving mechanisms |

Aerospace Industry | |

Aerospace Equipment Manufacturing | Aircraft component processing machine tools, satellite component assembly equipment, rocket engine test bench guide mechanisms |

Aerospace Onboard Equipment | Aircraft landing gear guide mechanisms, avionics equipment slide rails, satellite attitude adjustment mechanisms, UAV flight control systems |

Printing & Packaging Industry | |

Printing Machinery | Digital printers, gravure printers, flexographic printers, screen printers, label printers |

Packaging Machinery | Automatic packaging machines, sealing machines, labeling machines, wrapping machines, palletizing packaging production lines, food packaging equipment |

New Energy Industry | |

Photovoltaic Equipment | PV module string welders, laminators, edge trimmers, PV cell inspection equipment |

Wind Power Equipment | Wind turbine blade adjustment mechanisms, nacelle guide components, wind power gearbox guide mechanisms |

Modelo No. | Dimensiones de montaje (mm) Assembly (mm) | mounting Bolt for Rail | Basic Dinámico Load Rating | Basic Estático Load Rating | Momento nominal estático | Peso | |||||

H | H1 | N | (mm) | C(kN) | CO(kN) | MR kN-m | MP kN-m | M YkN-m | Block kg | Rail kg/m | |

HGH15CA | 28 | 4.3 | 9.5 | M4x16 | 11.38 | 16.97 | 0.12 | 0.10 | 0.10 | 0.18 | 1.45 |

HGH20CA | 30 | 4.6 | 12 | M5x16 | 17.75 | 27.76 | 0.27 | 0.20 | 0.20 | 0.30 | 2.21 |

HGH20HA | 21.18 | 35.90 | 0.35 | 0.35 | 0.35 | 0.39 | |||||

HGH25CA | 40 | 5.5 | 12.5 | M6x20 | 26.48 | 36.49 | 0.42 | 0.33 | 0.33 | 0.51 | 3.21 |

HGH25HA | 32.75 | 49.44 | 0.56 | 0.57 | 0.57 | 0.69 | |||||

HGH30CA | 45 | 6 | 16 | M8x25 | 38.74 | 52.19 | 0.66 | 0.53 | 0.53 | 0.88 | 4.47 |

HGH30HA | 42.27 | 69.16 | 0.88 | 0.92 | 0.92 | 1.16 | |||||

HGH35CA | 55 | 7.5 | 18 | M8x25 | 49.52 | 69.16 | 1.16 | 0.81 | 0.81 | 1.45 | 6.30 |

HGH35HA | 60.21 | 91.63 | 1.54 | 1.40 | 1.40 | 1.92 | |||||

HGH45CA | 70 | 9.5 | 20.5 | M12x35 | 77.57 | 102.71 | 1.98 | 1.55 | 1.55 | 2.73 | 10.41 |

HGH45HA | 94.54 | 136.46 | 2.63 | 2.68 | 2.68 | 3.61 | |||||

HGH55CA | 80 | 13 | 23.5 | M14x45 | 114.44 | 148.33 | 3.69 | 2.64 | 2.64 | 4.17 | 15.08 |

HGH55HA | 139.35 | 196.20 | 4.88 | 4.57 | 4.57 | 5.49 | |||||

HGH65CA | 90 | 15 | 31.5 | M16x50 | 163.63 | 215.33 | 6.65 | 4.27 | 4.27 | 7.00 | 21.18 |

HGH65HA | 208.36 | 303.13 | 9.38 | 7.38 | 7.38 | 9.82 | |||||

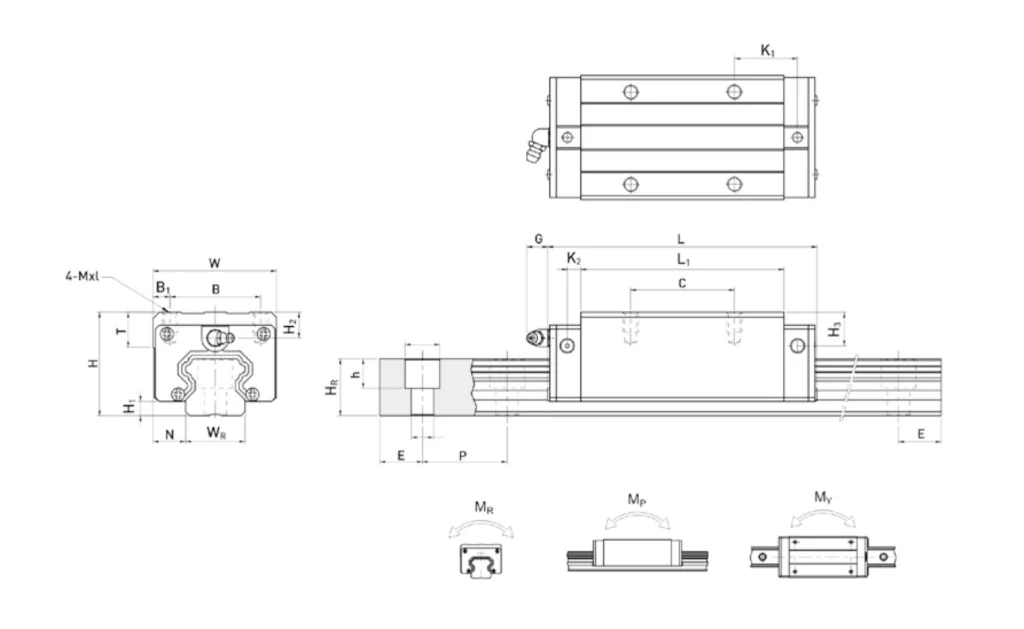

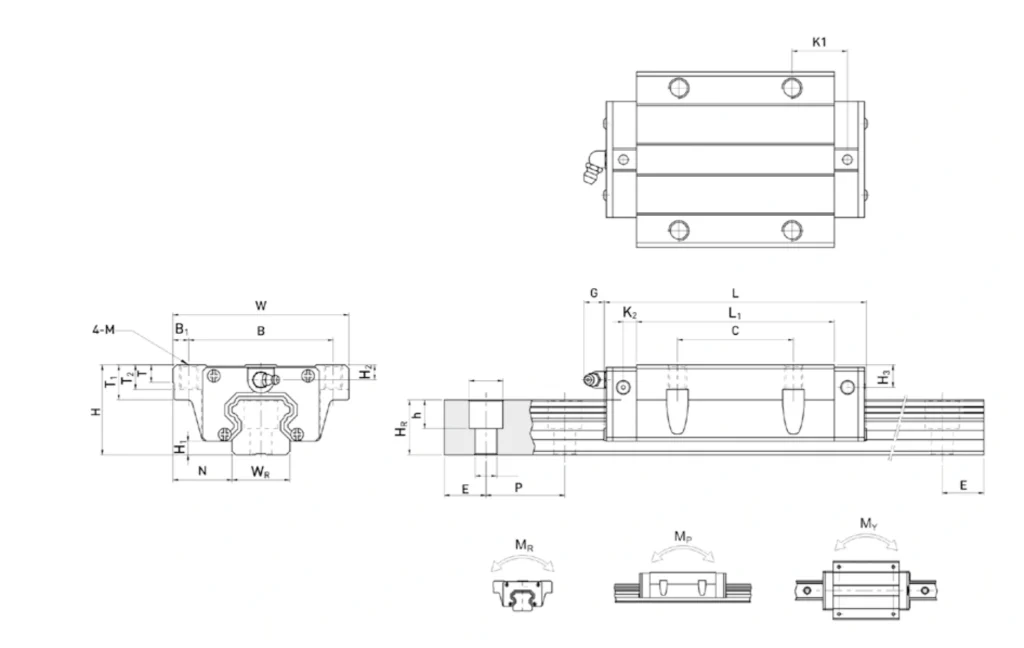

Modelo No. | Dimensions of Black (mm) | Dimensions of Rail (mm) | ||||||||||||||||||

W | B | B1 | C | L1 | L | K1 | K2 | G | Mxl | T | H2 | H3 | WR | HR | D | h | d | P | E | |

HGH15CA | 34 | 26 | 4 | 26 | 39.4 | 61.4 | 10 | 4.85 | 5.3 | M4x5 | 6 | 7.95 | 7.7 | 15 | 15 | 7.5 | 5.3 | 4.5 | 60 | 20 |

HGH20CA | 44 | 32 | 6 | 36 | 50.5 | 77.5 | 12.25 | 6 | 12 | M5x6 | 8 | 6 | 6 | 20 | 17.5 | 9.5 | 8.5 | 6 | 60 | 20 |

HGH20HA | 50 | 65.2 | 92.2 | 12.6 | ||||||||||||||||

HGH25CA | 48 | 35 | 6.5 | 35 | 58 | 84 | 15.7 | 6 | 12 | M6x8 | 8 | 10 | 9 | 23 | 22 | 11 | 9 | 7 | 60 | 20 |

HGH25HA | 50 | 78.6 | 104.6 | 18.5 | ||||||||||||||||

HGH30CA | 60 | 40 | 10 | 40 | 70 | 97.4 | 20.25 | 6 | 12 | M8x10 | 8.5 | 9.5 | 13.8 | 28 | 26 | 14 | 12 | 9 | 80 | 20 |

HGH30HA | 60 | 93 | 120.4 | 21.75 | ||||||||||||||||

HGH35CA | 70 | 50 | 10 | 50 | 80 | 112.4 | 20.6 | 7 | 12 | M8x12 | 10.2 | 16 | 19.6 | 34 | 29 | 14 | 12 | 9 | 80 | 20 |

HGH35HA | 72 | 105.8 | 138.2 | 22.5 | ||||||||||||||||

HGH45CA | 86 | 60 | 13 | 60 | 97 | 139.4 | 23 | 10 | 12.9 | M10x17 | 16 | 18.5 | 30.5 | 45 | 38 | 20 | 17 | 14 | 105 | 22.5 |

HGH45HA | 80 | 128.8 | 171.2 | 28.9 | ||||||||||||||||

HGH55CA | 100 | 75 | 12.5 | 75 | 117.7 | 166.7 | 27.35 | 11 | 12.9 | M12x18 | 17.5 | 22 | 29 | 53 | 44 | 23 | 20 | 16 | 120 | 30 |

HGH55HA | 95 | 155.8 | 204.8 | 36.4 | ||||||||||||||||

HGH65CA | 126 | 76 | 25 | 70 | 144.2 | 200.2 | 43.1 | 14 | 12.9 | M16x20 | 25 | 15 | 15 | 63 | 53 | 26 | 22 | 18 | 150 | 35 |

HGH65HA | 120 | 203.6 | 259.6 | 47.8 | ||||||||||||||||

Note: 1kgf=9.81N

Modelo No. | Dimensiones de montaje (mm) Assombly( mm ) | Mounting Bolt for Rail | Basic Dynamic Load Rating | Clasificación de carga estática básica Load Rating | Momento nominal estático | Peso | |||||

MR kN-m | MP kN-m | MY kN-m | Block kg | Rail kg/m | |||||||

H | H1 | N | ( mm ) | C(kN) | CO(kN) | ||||||

HGW15CC | 24 | 4.3 | 16 | M4x16 | 11.38 | 16.97 | 0.12 | 0.10 | 0.10 | 0.17 | 1.45 |

HGW20CC | 30 | 4.6 | 21.5 | M5x16 | 17.75 | 27.76 | 0.27 | 0.20 | 0.20 | 0.40 | 2.21 |

HGW20HA | 21.18 | 35.90 | 0.35 | 0.35 | 0.35 | 0.52 | |||||

HGW25CC | 36 | 5.5 | 23.5 | M6x20 | 26.48 | 36.49 | 0.42 | 0.33 | 0.33 | 0.59 | 3.21 |

HGW25HA | 32.75 | 49.44 | 0.56 | 0.57 | 0.57 | 0.80 | |||||

HGW30CC | 42 | 6 | 31 | M8x25 | 38.74 | 52.19 | 0.66 | 0.53 | 0.53 | 1.09 | 4.47 |

HGW30HA | 47.27 | 69.16 | 0.88 | 0.92 | 0.92 | 1.44 | |||||

HGW35CC | 48 | 7.5 | 33 | M8x25 | 49.52 | 69.16 | 1.16 | 0.81 | 0.81 | 1.56 | 6.30 |

HGW35HA | 60.21 | 91.63 | 1.54 | 1.40 | 1.40 | 2.06 | |||||

HGW45CC | 60 | 9.5 | 37.5 | M12x35 | 77.57 | 102.71 | 1.98 | 1.55 | 1.55 | 2.79 | 10.41 |

HGW45HA | 94.54 | 136.46 | 2.63 | 2.68 | 2.68 | 3.69 | |||||

HGW55CC | 70 | 13 | 43.5 | M14x45 | 114.44 | 148.33 | 3.69 | 2.64 | 2.64 | 4.52 | 15.08 |

HGW55HA | 139.35 | 196.20 | 4.88 | 4.57 | 4.57 | 5.96 | |||||

HGW65CC | 90 | 15 | 53.5 | M16x50 | 163.63 | 215.33 | 6.65 | 4.27 | 4.27 | 9.17 | 21.18 |

HGW65HA | 208.36 | 303.13 | 9.38 | 7.38 | 7.38 | 12.89 | |||||

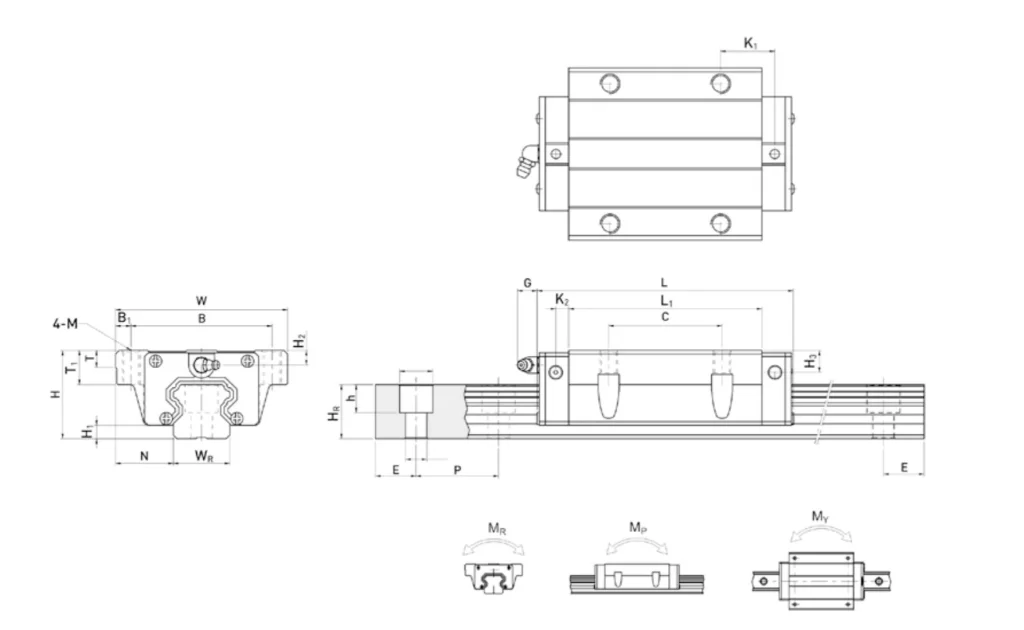

Modelo No. | Dimensions of Black ( mm ) | Dimensions of Rail ( mm ) | |||||||||||||||||||

W | B | B1 | C | L1 | L | K1 | K2 | G | M | T | T1 | H2 | H3 | WR | HR | D | h | d | P | E | |

HGW15CC | 47 | 38 | 4.5 | 30 | 39.6 | 61.4 | 8 | 4.85 | 5.3 | M5 | 6 | 8.9 | 3.95 | 3.7 | 15 | 15 | 7.5 | 5.3 | 4.5 | 60 | 20 |

HGW20CC | 63 | 53 | 5 | 40 | 50.5 | 77.5 | 10.25 | 6 | 12 | M6 | 8 | 10 | 6 | 6 | 20 | 17.5 | 9.5 | 8.5 | 6 | 60 | 20 |

HGW20HA | 65.2 | 92.2 | 17.6 | ||||||||||||||||||

HGW25CC | 70 | 57 | 6.5 | 45 | 58 | 84 | 10.7 | 6 | 12 | M8 | 8 | 14 | 6 | 5 | 23 | 22 | 11 | 9 | 7 | 60 | 20 |

HGW25HA | 78.6 | 104.6 | 21 | ||||||||||||||||||

HGW30CC | 90 | 72 | 9 | 52 | 70 | 97.4 | 14.25 | 6 | 12 | M10 | 8.5 | 16 | 6.5 | 10.8 | 28 | 26 | 14 | 12 | 9 | 80 | 20 |

HGW30HA | 93 | 120.4 | 25.75 | ||||||||||||||||||

HGW35CC | 100 | 82 | 9 | 62 | 80 | 112.4 | 14.6 | 7 | 12 | M10 | 10.1 | 18 | 9 | 12.6 | 34 | 29 | 14 | 12 | 9 | 80 | 20 |

HGW35HA | 105.8 | 138.2 | 27.5 | ||||||||||||||||||

HGW45CC | 120 | 100 | 10 | 80 | 97 | 139.4 | 13 | 10 | 12.9 | M12 | 15.1 | 22 | 8.5 | 20.5 | 45 | 38 | 20 | 17 | 14 | 105 | 22.5 |

HGW45HA | 128.8 | 171.2 | 28.9 | ||||||||||||||||||

HGW55CC | 140 | 116 | 12 | 95 | 117.7 | 166.7 | 17.35 | 11 | 12.9 | M14 | 17.5 | 26.5 | 12 | 19 | 53 | 44 | 23 | 20 | 16 | 120 | 30 |

HGW55HA | 155.8 | 204.8 | 36.4 | ||||||||||||||||||

HGW65CC | 170 | 142 | 14 | 110 | 144.2 | 200.2 | 23.1 | 14 | 12.9 | M16 | 25 | 37.5 | 15 | 15 | 63 | 53 | 26 | 22 | 18 | 150 | 35 |

HGW65HA | 203.6 | 259.6 | 52.8 | ||||||||||||||||||

Note: 1kgf=9.81N

Modelo No. | Dimensiones de montaje (mm) Assombly( mm ) | Dimensions of Black ( mm ) | |||||||||||||||

H | H1 | N | W | B | B1 | C | L1 | L | K1 | K2 | G | M | T | T1 | H2 | H3 | |

HGW15CC | 24 | 4.3 | 16 | 47 | 38 | 4.5 | 30 | 39.4 | 61.4 | 8 | 4.85 | 5.3 | M5 | 6 | 8.9 | 3.95 | 3.7 |

HGW20CC | 30 | 4.6 | 21.5 | 63 | 53 | 5 | 40 | 50.5 | 77.5 | 10.25 | 6 | 12 | M6 | 8 | 10 | 6 | 6 |

HGW20HC | 65.2 | 92.2 | 17.6 | ||||||||||||||

HGW25CC | 36 | 5.5 | 23.5 | 70 | 57 | 6.5 | 45 | 58 | 84 | 10.7 | 6 | 12 | M8 | 8 | 14 | 6 | 5 |

HGW25HC | 78.6 | 104.6 | 21 | ||||||||||||||

HGW30CC | 42 | 6 | 31 | 90 | 72 | 9 | 52 | 70 | 97.4 | 14.25 | 6 | 12 | M10 | 8.5 | 16 | 6.5 | 10.8 |

HGW30HC | 93 | 120.4 | 25.75 | ||||||||||||||

HGW35CC | 48 | 7.5 | 33 | 100 | 82 | 9 | 62 | 80 | 112.4 | 14.6 | 7 | 12 | M10 | 10.1 | 18 | 9 | 12.6 |

HGW35HC | 105.8 | 138.2 | 27.5 | ||||||||||||||

HGW45CC | 60 | 9.5 | 37.5 | 120 | 100 | 10 | 80 | 97 | 139.4 | 13 | 10 | 12.9 | M12 | 15.1 | 22 | 8.5 | 20.5 |

HGW45HC | 128.8 | 171.2 | 28.9 | ||||||||||||||

HGW55CC | 70 | 13 | 43.5 | 140 | 116 | 12 | 95 | 117.7 | 166.7 | 17.35 | 11 | 12.9 | M14 | 17.5 | 26.5 | 12 | 19 |

HGW55HC | 155.8 | 204.8 | 36.4 | ||||||||||||||

HGW65CC | 90 | 15 | 53.5 | 170 | 142 | 14 | 110 | 144.2 | 200.2 | 23.1 | 14 | 12.9 | M16 | 25 | 37.5 | 15 | 15 |

HGW65HC | 203.6 | 259.6 | 52.8 | ||||||||||||||

Dimensions of Rail ( mm ) | Mounting Bolt for Rail | Basic Dynamic Load Rating | Clasificación de carga estática básica Load Rating | Momento nominal estático | Peso | |||||||||

MR kN-m | MP kN-m | MY kN-m | Block kg | Rail | ||||||||||

WR | HR | D | h | d | P | E | ( mm ) | C(kN) | CO(kN) | kg/m | ||||

15 | 15 | 7.5 | 5.3 | 4.5 | 60 | 20 | M4x16 | 11.38 | 16.97 | 0.12 | 0.10 | 0.10 | 0.17 | 1.45 |

20 | 17.5 | 9.5 | 8.5 | 6 | 60 | 20 | M5x16 | 17.75 | 27.76 | 0.27 | 0.20 | 0.20 | 0.40 | 2.21 |

21.18 | 35.90 | 0.35 | 0.35 | 0.35 | 0.52 | |||||||||

23 | 22 | 11 | 9 | 7 | 60 | 20 | M6x20 | 26.48 | 36.49 | 0.42 | 0.33 | 0.33 | 0.59 | 3.21 |

32.75 | 49.44 | 0.56 | 0.57 | 0.57 | 0.80 | |||||||||

28 | 26 | 14 | 12 | 9 | 80 | 20 | M8x25 | 38.74 | 52.19 | 0.66 | 0.53 | 0.53 | 1.09 | 4.47 |

47.27 | 69.16 | 0.88 | 0.92 | 0.92 | 1.44 | |||||||||

34 | 29 | 14 | 12 | 9 | 80 | 20 | M8x25 | 49.52 | 69.16 | 1.16 | 0.81 | 0.81 | 1.56 | 6.30 |

60.21 | 91.63 | 1.54 | 1.40 | 1.40 | 2.06 | |||||||||

45 | 38 | 20 | 17 | 14 | 105 | 22.5 | M12x35 | 77.57 | 102.71 | 1.98 | 1.55 | 1.55 | 2.79 | 10.41 |

94.54 | 136.46 | 2.63 | 2.68 | 2.68 | 3.69 | |||||||||

53 | 44 | 23 | 20 | 16 | 120 | 30 | M14x45 | 114.44 | 148.33 | 3.69 | 2.64 | 2.64 | 4.52 | 15.08 |

139.35 | 196.20 | 4.88 | 4.57 | 4.57 | 5.96 | |||||||||

63 | 53 | 26 | 22 | 18 | 150 | 35 | M16x50 | 163.63 | 215.33 | 6.65 | 4.27 | 4.27 | 9.17 | 21.18 |

208.36 | 303.13 | 9.38 | 7.38 | 7.38 | 12.89 | |||||||||

Note: 1kgf=9.81N

FAQ

CAGRI BEARINGS

Website:www.camcjsw-bearings.com

SINO-MACHINERY AGRO-DEVELOPMENT INVESTMENT CO., LTD. JIANGSU BRANCH

JIANGSU WALLONG-HSIN MACHINERY ENGINEERING CORPORATION LTD.

TEL:+86-510-8273 6527(Business)

+86-510-8270 1813(General)

FAX:+86-510-8272 5039/ 8271 0822

E-MAIL:guchenglong@camcjsw.com

camcjsw@camcjsw.com(General)