High-Precision Rod End and Spherical Plain Bearings--CAGRI Bearings

Product Overview

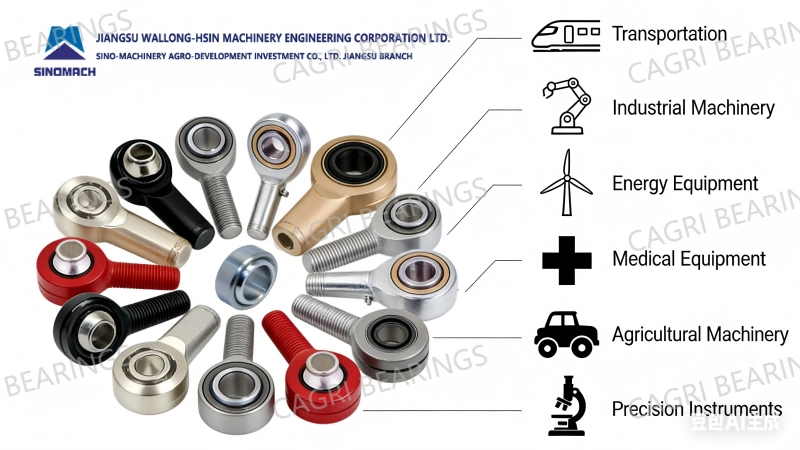

Cagri Bearings- Professional Supplier of Rod End and Spherical Plain Bearings. Rod End and Spherical Plain Bearings are crucial high-precision articulating connectors in the mechanical transmission field, with core functions of achieving multi-dimensional angular compensation, low-friction rotation, and reciprocating oscillating motion transmission, widely used in various equipment requiring dynamic attitude adjustment. In terms of classification, Rod End Bearings are mainly divided into Female Thread (e.g., SA series) and Male Thread (e.g., SI series), with derived sub-types such as left-hand thread and with lock nut for special scenarios; Spherical Plain Bearings are classified into Open Type (e.g., GE series), Double Sealed Type (e.g., GE…2RS series), Lubrication Groove/Hole Type (e.g., GEEW series), as well as two major sub-categories: self-lubricating type and periodically lubricated type based on structural characteristics. Product models are fully compatible with international mainstream standards, including SAE AS81820, ISO 12240, DIN 40822, etc., with precision grades ranging from P0 (normal precision) to P5 (high precision). Among them, P5/P6 grades are commonly used in industrial automation and aerospace fields, and the bore diameter ranges from 2mm (for precision instruments) to over 300mm (for large construction machinery). Material selection is highly flexible: the outer ring is mainly made of high-carbon chromium bearing steel GCr15 (quenched and tempered, hardness HRC60-64), stainless steel 304/316 (for corrosion-resistant scenarios); the inner ring is matched with tin bronze bushings, copper alloy + PTFE self-lubricating composite materials, phosphated steel, etc. For extreme working conditions (high temperature >200℃, strong corrosion), Inconel alloy or ceramic materials can be selected to fully meet diverse requirements such as wear resistance, impact resistance, corrosion resistance, and high temperature resistance.

What is Rod End and Spherical Plain Bearings?

Rod End and Spherical Plain Bearings are essentially “low-friction motion transmission components with spherical contact interfaces”. Their core design logic is to achieve large-angle deflection (maximum deflection angle 15°-30° for Rod End Bearings, 30°-45° for Spherical Plain Bearings) through precise cooperation between the inner ring spherical surface and outer ring spherical surface, while bearing radial load, axial load or combined load, effectively compensating for installation deviations, vibration deformation, and displacement errors caused by thermal expansion and contraction during equipment operation.

In terms of application scenarios and adapted products, the two types of bearings have their own focuses and complement each other:

Rod End Bearings, with threaded connection structure, are more suitable for end connection of linkages, control systems, and transmission rods. Typical applications include: automotive industry (suspension control arms, steering tie rods, transmission shift linkages, shock absorber connection ends), aerospace (aircraft control stick joints, landing gear retraction mechanisms, satellite attitude control linkages), industrial automation (robotic arm end effectors, linear module connection joints, conveyor line steering mechanisms), medical equipment (rehabilitation equipment joints, surgical instrument transmission rods); adapted core components include hydraulic piston rods, servo motor output shafts, gear rack mechanisms, ball screw assemblies, etc.

Spherical Plain Bearings, with stronger load-bearing capacity and adaptability to heavy-load low-speed scenarios, are widely used in: construction machinery (excavator hydraulic cylinder piston rods, crane luffing arm joints, loader steering knuckles), energy equipment (wind turbine yaw system joints, pitch mechanism bearings, hydraulic turbine governor link joints), rail transit (train bogie axle box bearings, brake system swing joints), agricultural machinery (tractor suspension lifting mechanisms, harvester reel joints, seeder adjustment linkages); adapted core components include large hydraulic actuators, heavy-duty transmission shafts, swing robotic arms, vibrating screen eccentric shafts, etc.

The two types of bearings jointly cover seven core fields: transportation, industrial manufacturing, energy and power, aerospace, medical equipment, agricultural machinery, and precision instruments, becoming key components to ensure stable equipment operation, improve transmission efficiency, and extend service life.

Ventajas del rodamiento de bolas CAGRI EMQ

With years of experience in the Rod End and Spherical Plain Bearing industry, CAGRI has formed four core competitive advantages through technological innovation and strict quality control, establishing a brand image of “high precision, high reliability, and high adaptability” in the global market:

1.Ultimate Wear-Resistant Self-Lubricating Technology: Exclusively adopts “PTFE + carbon fiber + nano-ceramic particle” composite self-lubricating bushing. Compared with traditional single PTFE material, the wear resistance is improved by 50%, and the friction coefficient is as low as 0.03-0.05 (0.1-0.15 for ordinary bearings), realizing lifelong maintenance-free lubrication or ultra-long lubrication cycle (>10,000 hours). It can operate stably in harsh environments such as dust, mud, high temperature (-50℃ to 250℃), and humidity, significantly reducing equipment maintenance costs and downtime.

2.Super Load-Bearing and Impact-Resistant Structure: The outer ring adopts an integrated process of “forging + integral quenching + precision grinding”, resulting in finer grains, 30% higher impact strength, and stable hardness of HRC62-64; the inner ring adopts a bimetallic composite structure (bearing steel base + wear-resistant liner), with a load-bearing capacity 20%-30% higher than the industry average. Among them, the radial load-bearing capacity can reach 200MPa, and the axial load-bearing capacity can reach 150MPa, which can easily cope with heavy-load, frequent start-stop, and impact load scenarios (such as construction machinery excavation operations, wind turbine gust impact).

3.Micron-Level Precision Control and Consistency: Introduces German imported CNC machining centers and coordinate measuring machines (measurement accuracy ±0.001mm), with key dimensions (spherical radius, fit clearance, thread precision) tolerances controlled within ±0.005mm, far higher than ISO standard requirements; adopts automated production lines and batch traceability systems to ensure that the dimensional consistency of products of the same model is >99.5%, effectively reducing the difficulty of equipment installation and commissioning, and improving the motion precision and stability of the transmission system.

4.Full-Scenario Customized Solutions: Provides full-dimensional customization services from material, structure, size to function for the special needs of different industries: material customization includes high-temperature alloy (Inconel 718), corrosion-resistant stainless steel (316L), ceramic coating, etc.; structure customization can design special threads (left-hand, fine thread), with dust cover/sealing ring, integrated sensors (temperature/vibration monitoring), etc.; size customization supports non-standard bore diameter and length, with the minimum bore diameter up to 1mm (for precision instruments) and the maximum bore diameter up to 500mm (for large equipment); at the same time, it provides value-added services such as installation guidance, working condition simulation testing, and life prediction, perfectly adapting to the personalized needs of niche scenarios and high-end equipment.

Solicitud

Transportation | |

Automotive Industry | Suspension control arms, steering tie rods, transmission shift linkages, shock absorber connection ends, chassis stabilizer bar joints |

Rail Transit | Train bogie joints, brake system swing linkages, door opening/closing mechanisms, traction system connection ends |

Marine Equipment | Propulsion system drive shaft joints, steering gear control mechanisms, deck machinery linkages, navigation equipment adjustment joints |

Aerospace | Aircraft control stick joints, landing gear retraction mechanisms, engine linkages, satellite attitude control linkages, rocket propulsion system joints |

Industrial Machinery | |

Automation & Robotics | Industrial robot joints, robotic arm end effectors, linear module connectors, conveyor line steering mechanisms |

Machine Tools | Spindle swing mechanisms, worktable adjustment linkages, turret steering joints, hydraulic fixture connection ends |

Hydraulic Machinery | Hydraulic cylinder piston rods, hydraulic valve control levers, hydraulic motor connection joints, high-pressure oil pipe connectors |

General Machinery | Compressor connecting rod joints, pump swing mechanisms, fan adjustment linkages, printer roller joints |

Energy Equipment | |

Wind Power | Wind turbine yaw system joints, pitch mechanism bearings, nacelle shock absorption connection ends, tower adjustment linkages |

Hydropower | Hydraulic turbine governor link joints, generator rotor connection ends, gate opening/closing mechanism joints |

Solar Energy Equipment | Solar panel tracking system joints, condenser adjustment linkages, solar panel angle adjustment connectors |

Nuclear Energy Equipment | Reactor control rod drive mechanism joints, cooling system circulation pump linkages, containment seal mechanism connectors |

Medical Equipment | |

Rehabilitation Equipment | Wheelchair joints, prosthetic connectors, rehabilitation trainer swing linkages, massage chair robotic arm joints |

Surgical Instruments | Minimally invasive surgical instrument transmission rods, operating table adjustment joints, medical robot joints |

Maquinaria agrícola | |

Farming Machinery | Tractor suspension lifting mechanisms, harvester reel joints, seeder row spacing adjustment linkages |

Irrigation Equipment | Sprinkler rotation joints, drip irrigation system adjustment linkages, water pipe steering connectors |

Harvesting Machinery | Combine harvester header adjustment joints, thresher transmission linkages, straw returning machine swing mechanisms |

Precision Instruments | |

Electronic Equipment | Semiconductor equipment robotic arm joints, lithography machine adjustment linkages, testing instrument swing mechanisms |

Measuring Equipment | Coordinate measuring machine motion joints, laser rangefinder adjustment linkages, precision balance swing connectors |

FAQ

CAGRI BEARINGS

Website:www.camcjsw-bearings.com

SINO-MACHINERY AGRO-DEVELOPMENT INVESTMENT CO., LTD. JIANGSU BRANCH

JIANGSU WALLONG-HSIN MACHINERY ENGINEERING CORPORATION LTD.

TEL:+86-510-8273 6527(Business)

+86-510-8270 1813(General)

FAX:+86-510-8272 5039/ 8271 0822

E-MAIL:guchenglong@camcjsw.com

camcjsw@camcjsw.com(General)