High-Precision Bearing Snap Rings--CAGRI Bearings

Product Overview

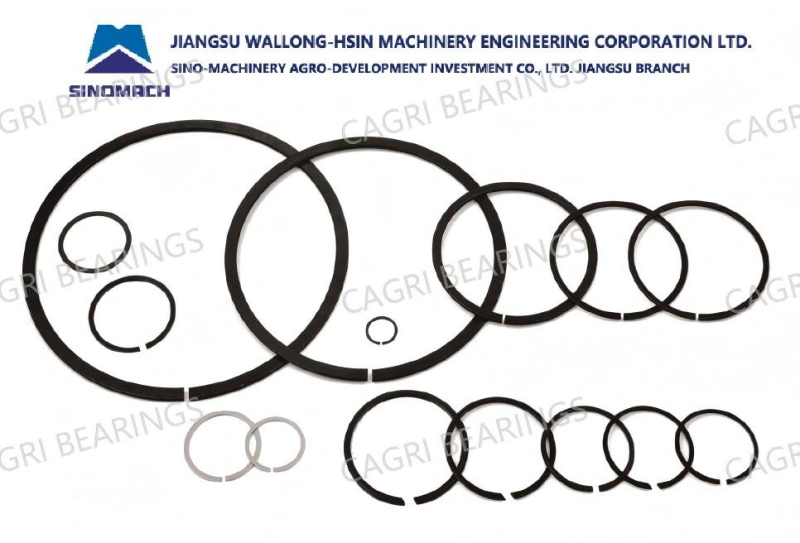

Cagri Bearings- Professional Supplier of Bearing Snap Rings. Bearing Snap Ring (also known as Bearing Retaining Ring) is an elastic fastening standard part used for axial fixation of bearings, shaft parts or hole parts. Its core function is to limit the axial displacement of parts in the assembly, prevent loosening caused by vibration or impact, and ensure the stable operation of the mechanical system. The core product categories are divided into Shaft-mounted Bearing Snap Rings and Hole-mounted Bearing Snap Rings according to the installation position; according to the manufacturing process, they are divided into Stamped Bearing Snap Rings and Coiled Bearing Snap Rings. Among them, the stamped type has become the mainstream in the market due to its low production cost and wide adaptation range. The models comply with international general standards (such as ISO 3056, DIN 471, ANSI B27.1). Common shaft-mounted models include GB/T 894.1-2017 (corresponding to ISO 3056) series and DIN 471 series; hole-mounted models include GB/T 893.1-2017 (corresponding to ISO 3057) series and ANSI B27.1 series, with specifications covering the shaft diameter/hole diameter range of 3mm-300mm. In terms of precision, the product dimensional tolerance is strictly controlled within ±0.02mm-±0.05mm, the surface roughness Ra≤1.6μm, and the elastic deformation meets the ISO 9001 quality system standard. The material is mainly high-strength spring steel (65Mn) ,chrome steel (100Cr6) and stainless steel (SUS304/SUS316); some products for high-temperature working conditions adopt alloy spring steel (50CrVA) to meet the corrosion resistance and high-temperature resistance requirements of different environments.

What is Bearing Snap Rings?

Bearing Snap Ring is a mechanical locking part that realizes quick installation and fastening by its own elastic deformation. It does not require additional fasteners (such as bolts, nuts) and forms axial positioning by snapping into the shaft groove or hole groove. It is widely used for fixing bearings, gears, pulleys, bushings and other parts in various mechanical devices. Its adaptation scenarios focus on mechanical systems that require compact structure, convenient assembly and reliable locking, and the adapted products cover multiple industries: in the general machinery field, it is adapted to core components of general machinery such as motor bearings, reducer bearings, and centrifugal pump bearings; in the automotive field, it is adapted to key automotive components such as engine crankshaft bearings, gearbox bearings, wheel hub bearings, and steering system bearings; in the construction machinery field, it is adapted to heavy equipment parts such as excavator hydraulic pump bearings, loader gearbox bearings, and crane winch bearings; in the electronic equipment field, it is adapted to precision components such as micro-motor bearings, printer bearings, and medical equipment (such as ventilator, centrifuge) bearings; in addition, it is also adapted to various bearings and shaft-hole parts in household appliances (air conditioning compressor bearings, washing machine motor bearings), aerospace (small aero-engine bearings), marine equipment (marine propulsion system bearings) and other fields. It is compatible with mainstream bearing types such as deep groove ball bearings, cylindrical roller bearings, and angular contact bearings, and adapts to various mechanical structures with shaft diameter/hole diameter of 3mm-300mm.

CAGRI Bearing Snap Ring Advantages

Relying on advanced stamping forming technology and strict quality control system, CAGRI Bearing Snap Ring (Stamped Retaining Ring) has formed five core competitive advantages, with strong competitiveness in the market:

- High-strength Material and Precision Stamping Process: Select high-purity 65Mn spring steel, SUS304/SUS316 stainless steel and 50CrVA alloy spring steel. The raw materials undergo strict composition testing and quenching-tempering treatment, with tensile strength up to 1200MPa-1500MPa and elastic recovery rate ≥95%; adopt high-precision CNC stamping equipment, with mold precision up to ±0.01mm, ensuring product dimensional consistency, and the tolerance is controlled within ±0.02mm, far exceeding the industry standard.

- Optimized Structural Design and Super Strong Locking Force: Optimize the cross-sectional structure according to different application scenarios, adopt arc or trapezoidal cross-sectional design, increase the contact area with the groove wall, and the locking force is increased by 20%-30%, effectively preventing axial movement of parts; the inner side of shaft-mounted snap rings and the outer side of hole-mounted snap rings are chamfered to reduce assembly resistance, avoid scratching the shaft or hole wall, and improve assembly efficiency.

- Excellent Corrosion Resistance and Fatigue Resistance: Various surface treatment processes are available, including galvanizing (Zn), nickel plating (Ni), chrome plating (Cr), passivation treatment and Dacromet coating. Among them, the Dacromet coated products can pass the salt spray test for more than 720 hours, and the corrosion resistance is significantly better than similar products; after multiple fatigue tests, the product can withstand more than 10⁶ elastic deformations without failure, and the service life is extended by more than 50% compared with ordinary snap rings, adapting to harsh working conditions such as high-frequency vibration and alternating high and low temperatures.

- Convenient Installation and Wide Adaptability: No complex installation tools are required, and assembly and disassembly can be quickly completed with snap ring pliers, greatly improving production efficiency; the product models are complete, covering the full specification range of 3mm-300mm, compatible with international standards such as ISO, DIN, ANSI and GB national standards, adapting to bearings and mechanical parts of different brands and types. At the same time, it supports customized slot dimensions and special material requirements to meet non-standard working condition applications.

- High Cost-effectiveness: Achieve large-scale production through automated production lines, reduce unit production costs, and the price is 12%-18% lower than that of similar competitors; the product has passed ISO 9001 and TS 16949 quality system certifications, and each batch of products undergoes multiple inspections such as dimensional inspection, elasticity test, with a qualified rate of 99.9%.

Application

Automotive Industry | |

Engine System | Crankshaft bearings, camshaft bearings, connecting rod bearings, water pump bearings, generator bearings |

Transmission & Chassis System | Gearbox bearings, drive shaft bearings, wheel hub bearings, steering knuckle bearings, shock absorber bearings |

Machinery Industry | |

Motor & Transmission Equipment | Asynchronous motor bearings, servo motor bearings, reducer bearings, gearbox bearings, coupling bearings |

Fluid Machinery | Centrifugal pump bearings, vane pump bearings, diaphragm pump bearings, fan bearings, compressor bearings |

Excavation Machinery | Excavator hydraulic pump bearings, swing motor bearings, travel motor bearings, arm cylinder bearings |

Loading & Lifting Machinery | Loader gearbox bearings, crane winch bearings, tower crane slewing bearings, forklift drive axle bearings |

Electronic & Precision Equipment Industry | |

Electronic Appliances | Micro DC motor bearings, printer bearings, copier bearings, projector bearings, audio equipment bearings |

Medical Equipment | Ventilator bearings, centrifuge bearings, infusion pump bearings, ultrasonic equipment bearings, dental handpiece bearings |

Household Appliance Industry | |

Agricultural Irrigation | Farmland irrigation water pumps, orchard drip irrigation water pumps, greenhouse spray water pumps |

Water Conservancy Projects | River dredging water pumps, reservoir drainage pumps, water conservancy hub water transmission pumps |

Marine and Offshore Engineering | |

White Goods | Air conditioning compressor bearings, refrigerator compressor bearings, washing machine motor bearings, dryer bearings, dishwasher water pump bearings |

Black Goods | TV cooling fan bearings, projector cooling bearings, audio speaker bearings, game console motor bearings |

Aerospace & Marine Industry | |

Aerospace Equipment | Small aero-engine bearings, UAV motor bearings, satellite attitude control motor bearings, rocket propulsion system bearings |

Marine Equipment | Marine propeller bearings, deck machinery bearings, marine generator bearings, seawater pump bearings, fuel pump bearings |

Rail Transit Industry | |

Locomotive & EMU | Traction motor bearings, gearbox bearings, wheel set bearings, braking system bearings, air conditioning unit bearings |

Urban Rail Transit | Metro traction bearings, light rail bogie bearings, tram drive bearings, platform screen door motor bearings |

FAQ

CAGRI BEARINGS

Website:www.camcjsw-bearings.com

SINO-MACHINERY AGRO-DEVELOPMENT INVESTMENT CO., LTD. JIANGSU BRANCH

JIANGSU WALLONG-HSIN MACHINERY ENGINEERING CORPORATION LTD.

TEL:+86-510-8273 6527(Business)

+86-510-8270 1813(General)

FAX:+86-510-8272 5039/ 8271 0822

E-MAIL:guchenglong@camcjsw.com

camcjsw@camcjsw.com(General)